Rico Press Brakes

The World's Strongest Press Brake

Hydraulic Press Brakes

Rico PRCN

Electric Press Brakes

Rico PRCE

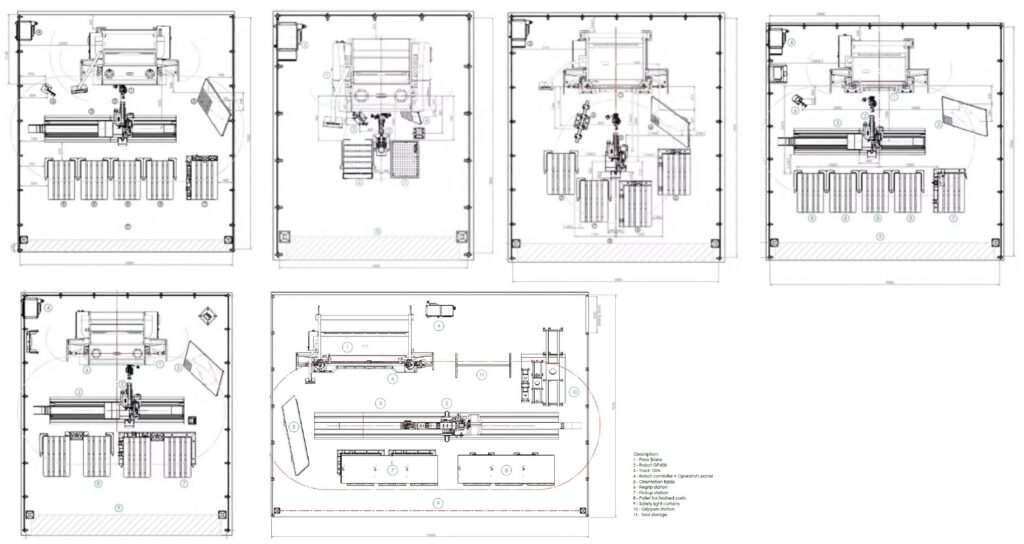

Robotic Bend Cells

Custom Designs

Additional Offerings Include:

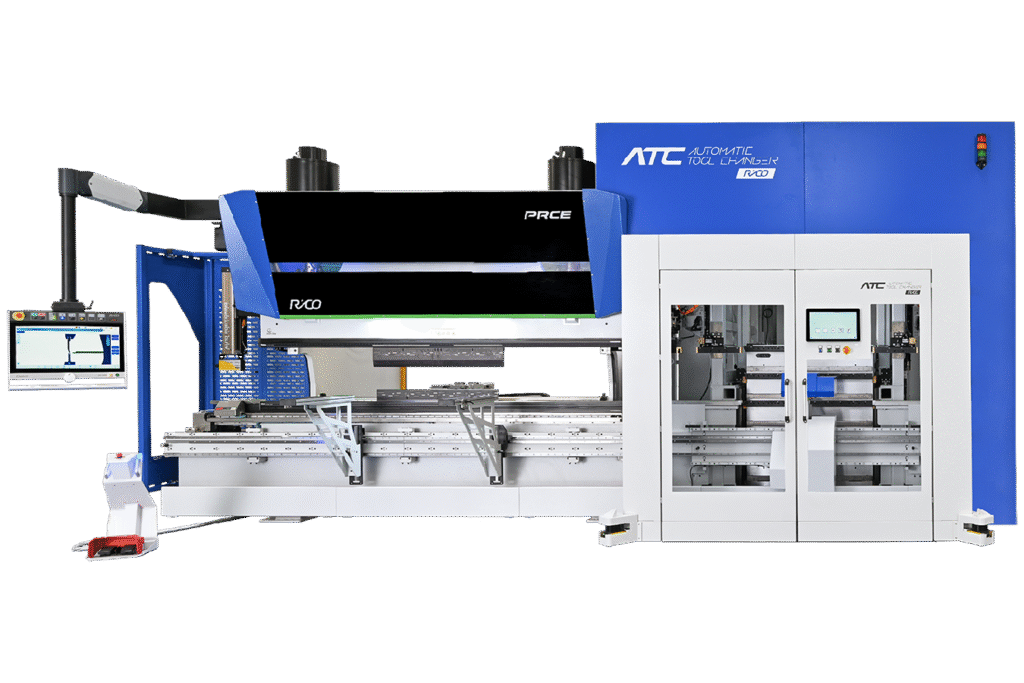

Automatic Tool Changer & Tandem Integration

Assisted Angle Correction

The Best in Safety Lasers

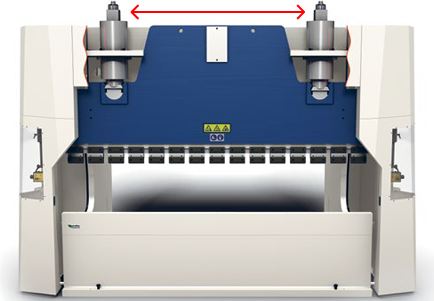

Lowest Deflection

The PRCN's unique design reduced ram deflection by 60% compared to standard designs.

Strongest Bed

The strongest bed on the market with a concentrated load limit of 67 tons per foot.

Shortest Cycle Times

Eco-Boost provides Hydraulic PRCN's with hybrid-like traverse speeds, with a mute point as low as .080"

Quality Options & Extras

Every feature is selected for premier performance. You can expect the best.

Machine Overview

Smooth Operation

Lowest Deflection

Under the extreme forces of bending, the ram of any press brake deflects in two planes, causing inconsistent bends and long setup times. Through unique design and material selection, the PRCN deflects 60% less than standard brakes. This results is more consistent and precise bending with less setup time.

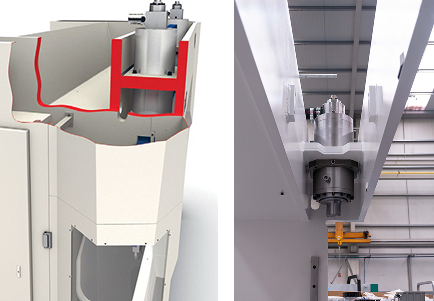

H-Box Frame

Centralized Cylinders

Triple-Guide Support

In-House Manufacturing

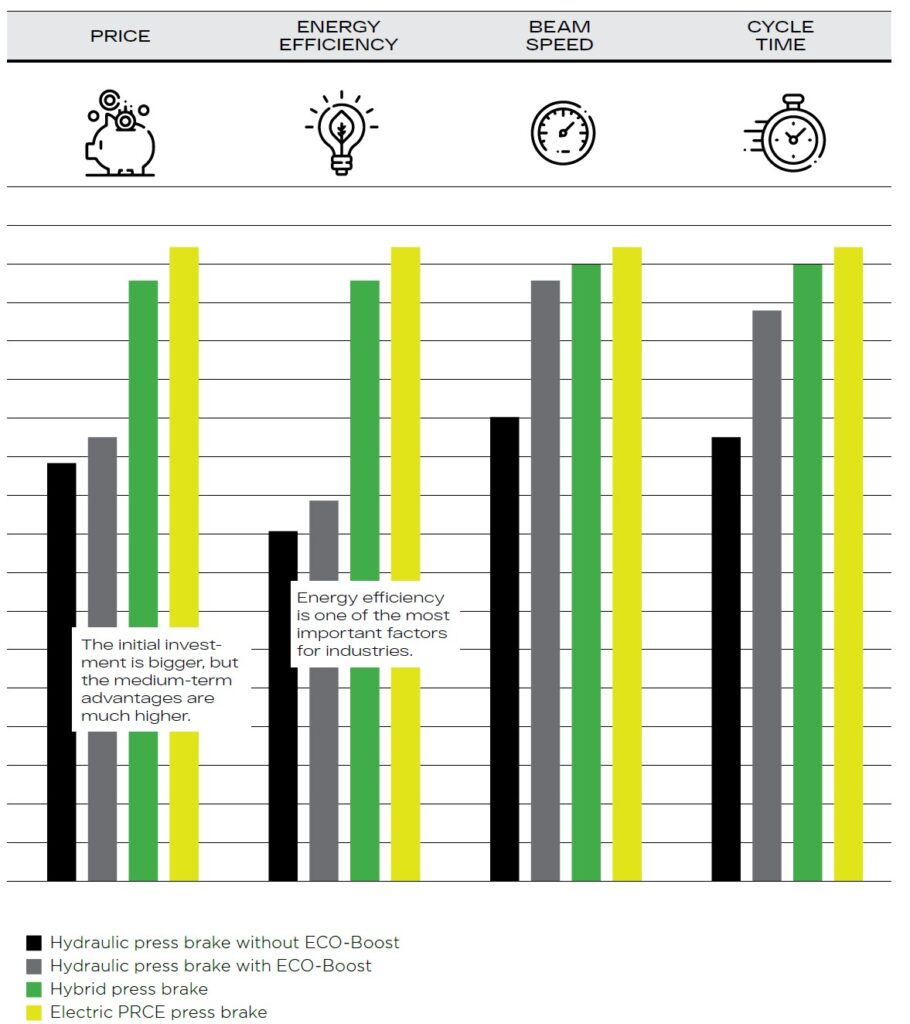

Shortest Cycle Times

Lightning fast ram and backgage with a minimized mute point

Minimized Maintenance

A simple design and absence of a hydraulic system translates to less wear and tear and reduced downtime.

Quiet and Energy Efficient

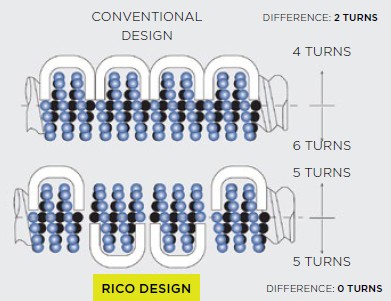

Planetary gears and a unique ball screw design improve energy efficiency by 40% and reduce noise by 70%.

Quality Options & Extras

Every feature is selected for premier performance. You can expect the best.

Machine Overview

Smooth Operation

Smooth, High-Speed Operation

Electric Press Brakes operate at lower tonnages, but provide fast, smooth and quiet operation. The high-capacity balls and planetary gearbox on Rico’s PRCE make it the fastest brake on the market today.

But cycle time is not just about ram speed. Fiessler AKAS 5M safety lasers on the PRCE can bring the mute point as low as 2mm, further minimizing cycle time.

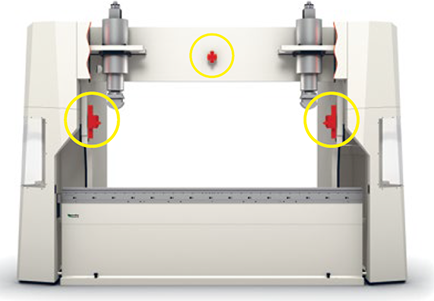

Planetary Gear

High Capacity Ball Screws

Minimized Mute Point

In-House Manufacturing

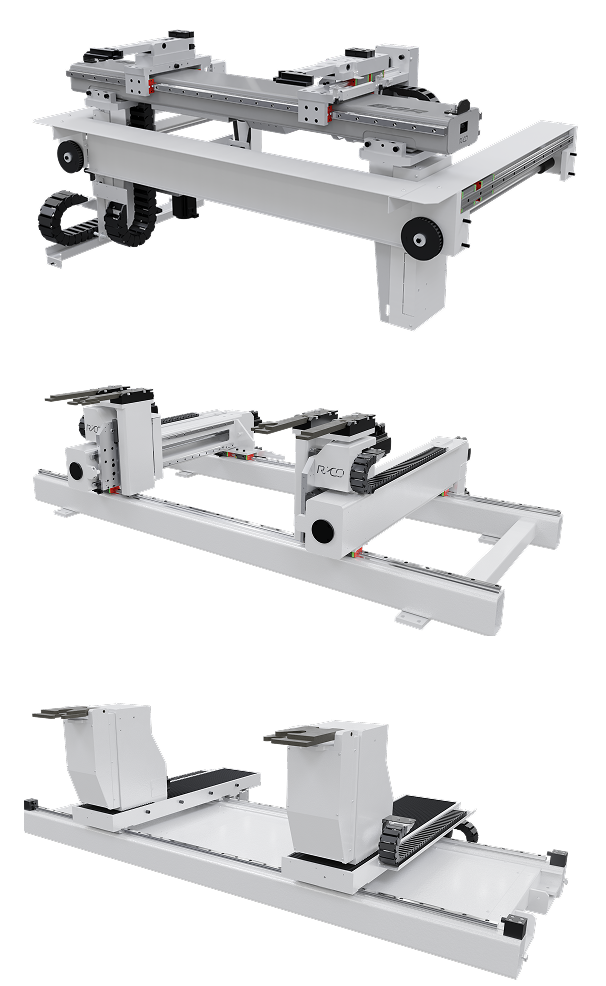

Best in Back Gauges

Premium Controls

Bend Cells, Tandem Brakes & Automatic Tool Changers

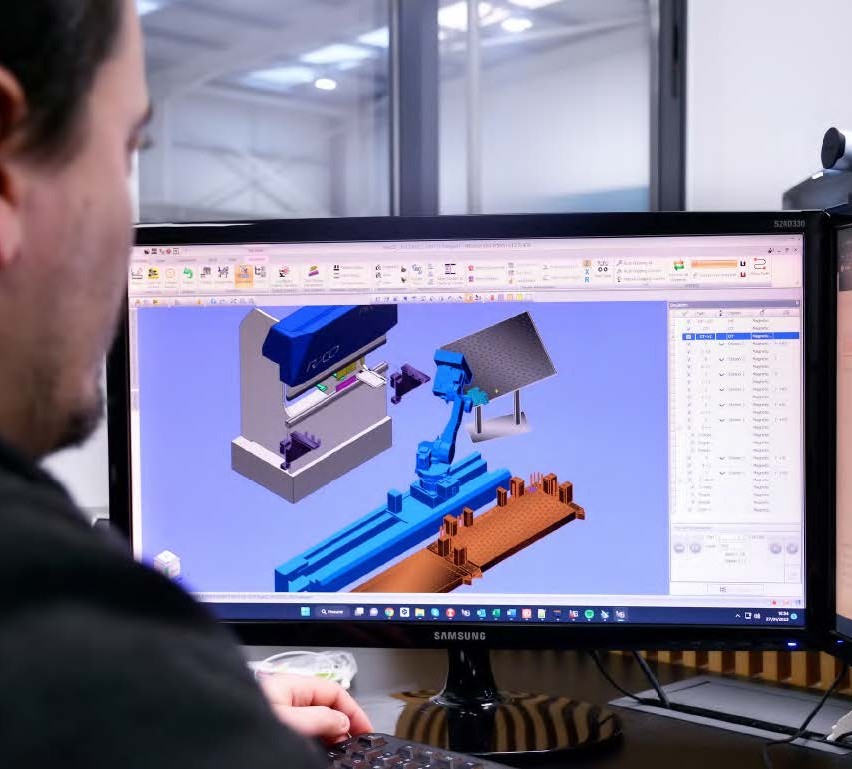

Robotic Integration

Designed for Your Application

The press brake, robot, grippers, and other features are specifically selected based on the part drawings you provide.

Ensure Productivity

See your parts bent on the production floor to ensure day one productivity of your cell.

15+ Years of Experience

As a long established brand in Europe, Rico brings over 15 years of robotic press brake experience.

Robotic Bend Cells

Smooth Operation

Custom Robotic Cells

With more than 15 years of experience in robotic bending, Rico custom designs each cell for every customer

This approach guarantees maximum flexibility, better integration and higher efficiency. By aligning every detail with your production goals, we ensure that our technology works for you – not the other way around.

Unlimited Layouts

Gripper Selection

Offline Programming

Yaskawa Robotics

Rico in Action

Twin Automatic Tool Changer

Watch this in-depth overview of the VisiWeld process - from "programming" to scanning and to welding. It really is that easy.

PRCN Overview

Excavator buckets require welding of variable thickness materials and are difficult to fabricate with the accuracy and consistency needed for standard robotic welding.

PRCE Overview

Manual auger welding is a difficult process but inconsistency in the auger flight makes robotic welding impossible. See how VisiWeld solves this problem.

70"/sec Bending Speeds

Watch this in-depth overview of the VisiWeld process - from "programming" to scanning and to welding. It really is that easy.

Part Programming

Excavator buckets require welding of variable thickness materials and are difficult to fabricate with the accuracy and consistency needed for standard robotic welding.

PRCE in Production

Manual auger welding is a difficult process but inconsistency in the auger flight makes robotic welding impossible. See how VisiWeld solves this problem.

Fairmont Support

Service Matters. Choose Wisely.

At Fairmont Machinery, we know equipment up-time is the key to productivity. There is nothing slower than a down machine. While many seem unconcerned with supporting their customers after a sale, we take a different approach at Fairmont.

Our hotline is staffed by senior service engineers who answer the phone 95% of the time. All our machines are equipped with video monitoring, so we can solve your problem and get you running as fast as possible. We have service offices across the USA.

Experience the difference with Fairmont.