NS Machines

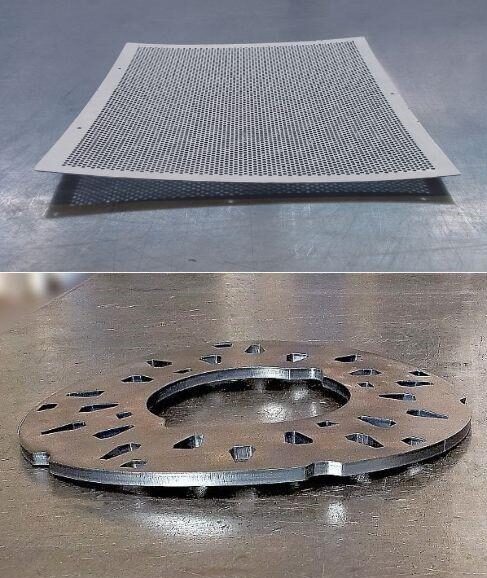

Edge Rounding & Deburring for Laser Cut Parts

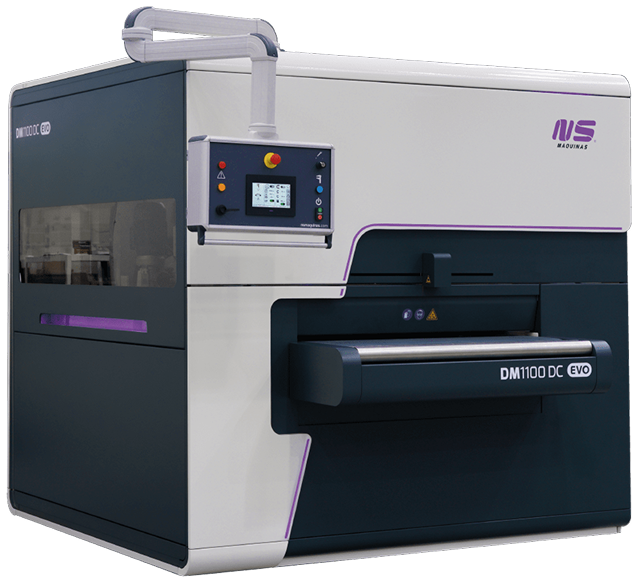

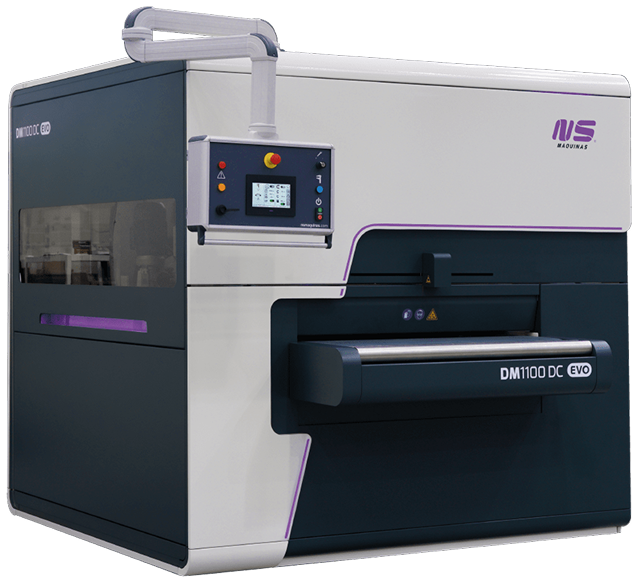

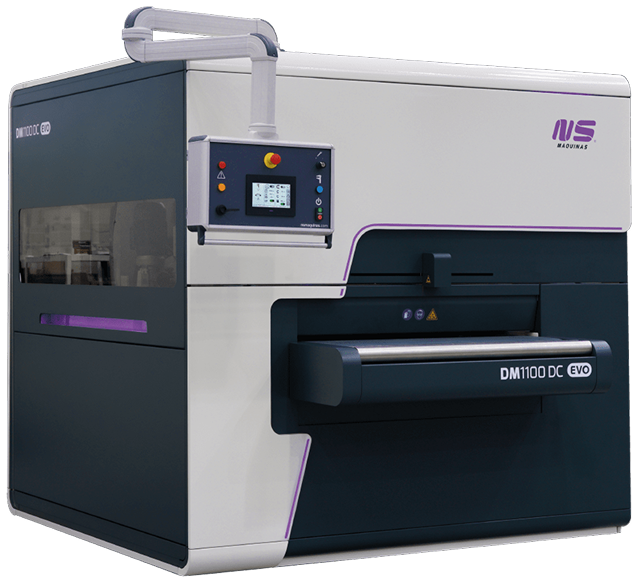

DM1100 DC

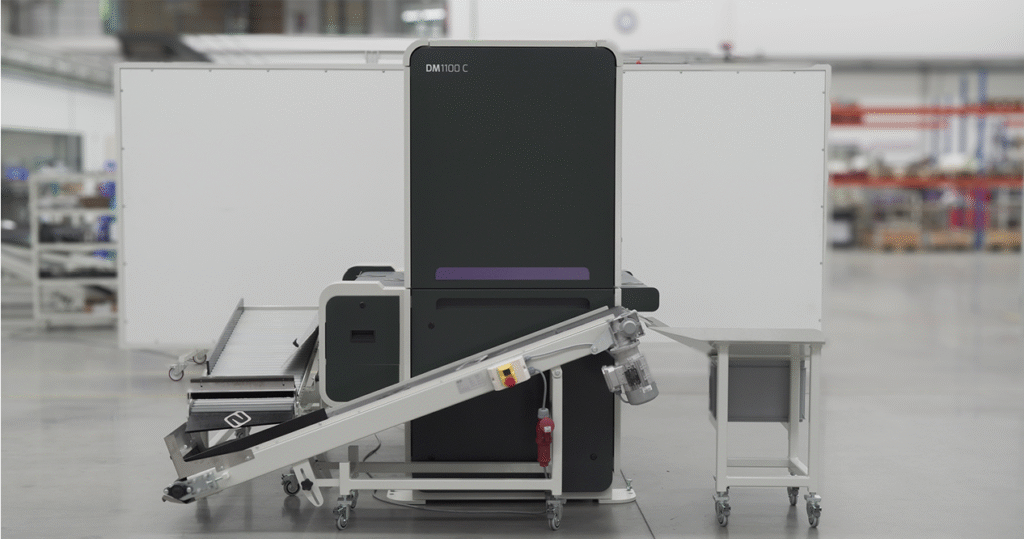

DM1100 ZC

DM1100 Z / C

The soft durometer drum flexes, maximizing grinding force on the edges of the part

The drum floats pneumatically, allowing it to rise and fall with the warp of plate material

The high-friction conveyor and magnet allow processing parts as small as a credit card

Technology that applies most of the grinding force to the edges, maximizing abrasive life

The floating, compliant drum makes the DC machine unique. By departing from the standard wide-belt design, the drum allows for more effective burr removal and processing of warped parts.

The drum floats pneumatically to follow the rise and fall of warping common to mild steel. Since the drum does not need to hold the abrasive under tension, like a wide belt, the drum can be softer. Softer contact focuses the grinding force on the edges of the part and maximizes burr removal without wasting abrasive on the part surface.

A standard wide-belt design - simple, reliable and proven.

Cross-Belts provide consistent results with a long consumable lifespan

The high-friction conveyor and wide belt allow for processing of parts as small as a credit card

Machines starting at $70k, delivered and installed with training

C machines provide only edge-rounding on steel but can remove even the worst aluminum burr

Z machines can remove heavy burr but leave a secondary sharp edge. Ideal for light burr on mild steels.

The best in flat and tube laser cutting with bevel options and powers up to 60kW. All backed by the industry's best service & support. Learn More

Robotic welding with vision and intelligence. Effortless offline program and vision to automatically adapt your program to each unique part. Learn More

Spend more time bending and less time correcting with Rico's unmatched precision and repeatability. Also offering custom robotic solutions. Learn More

The simplest way to edge round and debur. Efficiently remove dross, slag, and burr, and edge round. Easy to operate, optimized for laser and plasma. Learn More

Headquarters & Mailing Address

2110 Twin County Rd

Honey Brook, PA, 19344

United States

Main Phone Toll Free

+1 833 667 7889

information@fairmontmachinery.com

Coverage

USA Nationwide

©2026 Fairmont Concepts, Inc. All Rights Reserved. Fairmont Machinery is a division of Fairmont Concepts, Inc.