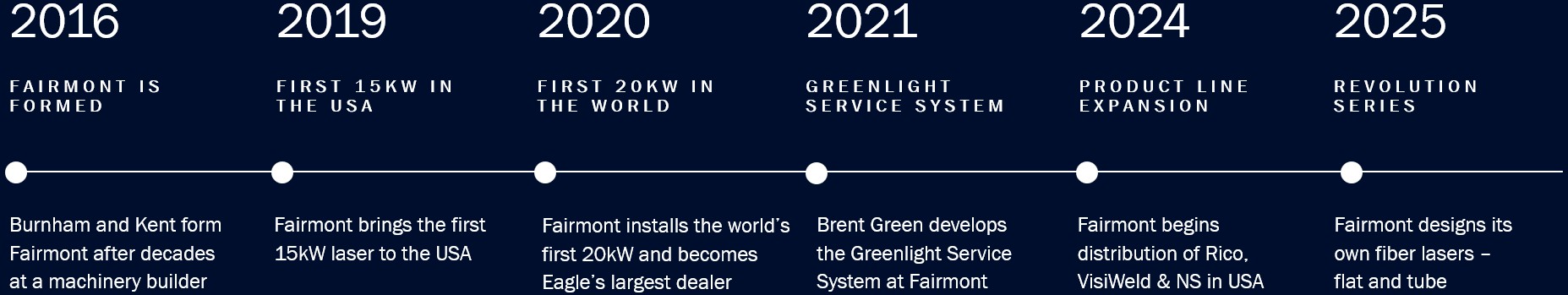

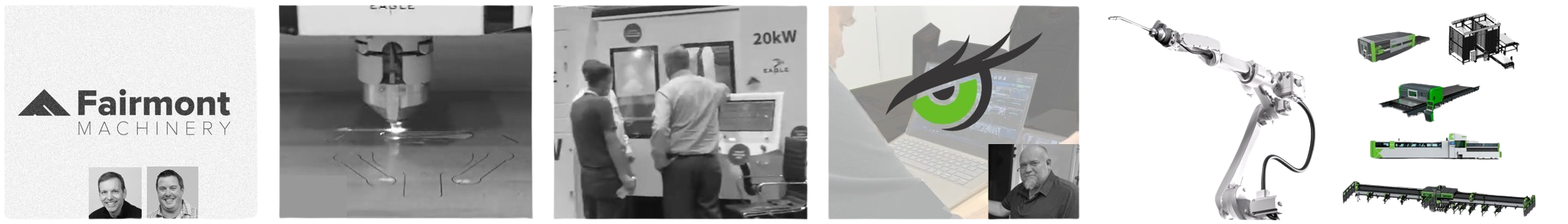

Fairmont Machinery was founded in 2016 with a simple but ambitious idea: find the best fabrication technology in the world, bring it to the United States, and support it with a service system that actually delivers.

Founded by Chip Burnham and Brian Kent, Fairmont was built differently from day one. While most machine tool dealers focus on a small region or a narrow product line, Fairmont set out to serve manufacturers across the entire United States—handling everything ourselves: parts, service, warranty, applications support, and long-term ownership.

Fairmont quickly became known for leading the industry—not following it. In 2018, Fairmont was selected as Eagle Laser’s exclusive U.S. dealer, at a time when Eagle had just six systems installed in the country. Over the next few years, Fairmont helped built one of the largest installed bases of advanced fiber lasers in North America.

Along the way, Fairmont consistently introduced technology ahead of the market. They were the first company in the U.S. to install 15kW, 20kW and 30kW fiber lasers in the US – becoming Eagle’s largest distributor in just two years. Today, Fairmont remains an industry leader in high-power cutting, representing their own line of flat and tube lasers designed and built to their own specifications – the Revolution Series.

Technology is only as good as the support behind it. In 2021, Brent Green (VP Service and Chief Operating Officer) created what has become Fairmont’s defining advantage: Fairmont GreenLight Service™.

GreenLight Service was designed from the ground up to eliminate downtime and frustration. It includes an industry-leading hotline call center that answers more than 92 percent of incoming calls with a senior technician ready to begin working immediately, Fairmont Overwatch Camera DVR™, a local (non-cloud) high-definition camera system that records machine activity and allows instant troubleshooting, and powerful remote diagnostics that often solve problems without a site visit. When on-site service is required, Fairmont responds quickly thanks to the best service engineer–to–machine ratio in the industry, with fewer than 15 machines per service engineer, all supported by a massive in-stock parts inventory.

Beginning in 2024, Fairmont expanded beyond laser cutting to offer a broader range of cutting-edge fabrication solutions. These include Fairmont VisiWeld AI, intelligent robotic welding with vision and adaptive control; NS Deburring Equipment, designed specifically for edge rounding and deburring laser- and plasma-cut parts; and Rico Press Brakes, widely regarded as the strongest and most accurate hydraulic and electric press brakes available, including custom robotic press brake cells.

Each product line was chosen using the same criteria Fairmont has always applied: best-in-class performance, long-term reliability, and real support.

Fairmont Machinery exists to raise the standard of what machine tool distribution should be.

We scour the globe for the best fabrication equipment, bring it to the United States, and support it with our renowned Fairmont GreenLight Service—so our customers can focus on making parts, growing their businesses, and staying competitive.

The best in flat and tube laser cutting with bevel options and powers up to 60kW. All backed by the industry's best service & support. Learn More

Robotic welding with vision and intelligence. Effortless offline program and vision to automatically adapt your program to each unique part. Learn More

Spend more time bending and less time correcting with Rico's unmatched precision and repeatability. Also offering custom robotic solutions. Learn More

The simplest way to edge round and debur. Efficiently remove dross, slag, and burr, and edge round. Easy to operate, optimized for laser and plasma. Learn More

Headquarters & Mailing Address

2110 Twin County Rd

Honey Brook, PA, 19344

United States

Main Phone Toll Free

+1 833 667 7889

information@fairmontmachinery.com

Coverage

USA Nationwide

©2026 Fairmont Concepts, Inc. All Rights Reserved. Fairmont Machinery is a division of Fairmont Concepts, Inc.